- Home

- >

- News

- >

- Company News

- >

- Accurately guarding the quality of aviation fuel, intelligently ushering in a new era of high efficiency and safety

Accurately guarding the quality of aviation fuel, intelligently ushering in a new era of high efficiency and safety

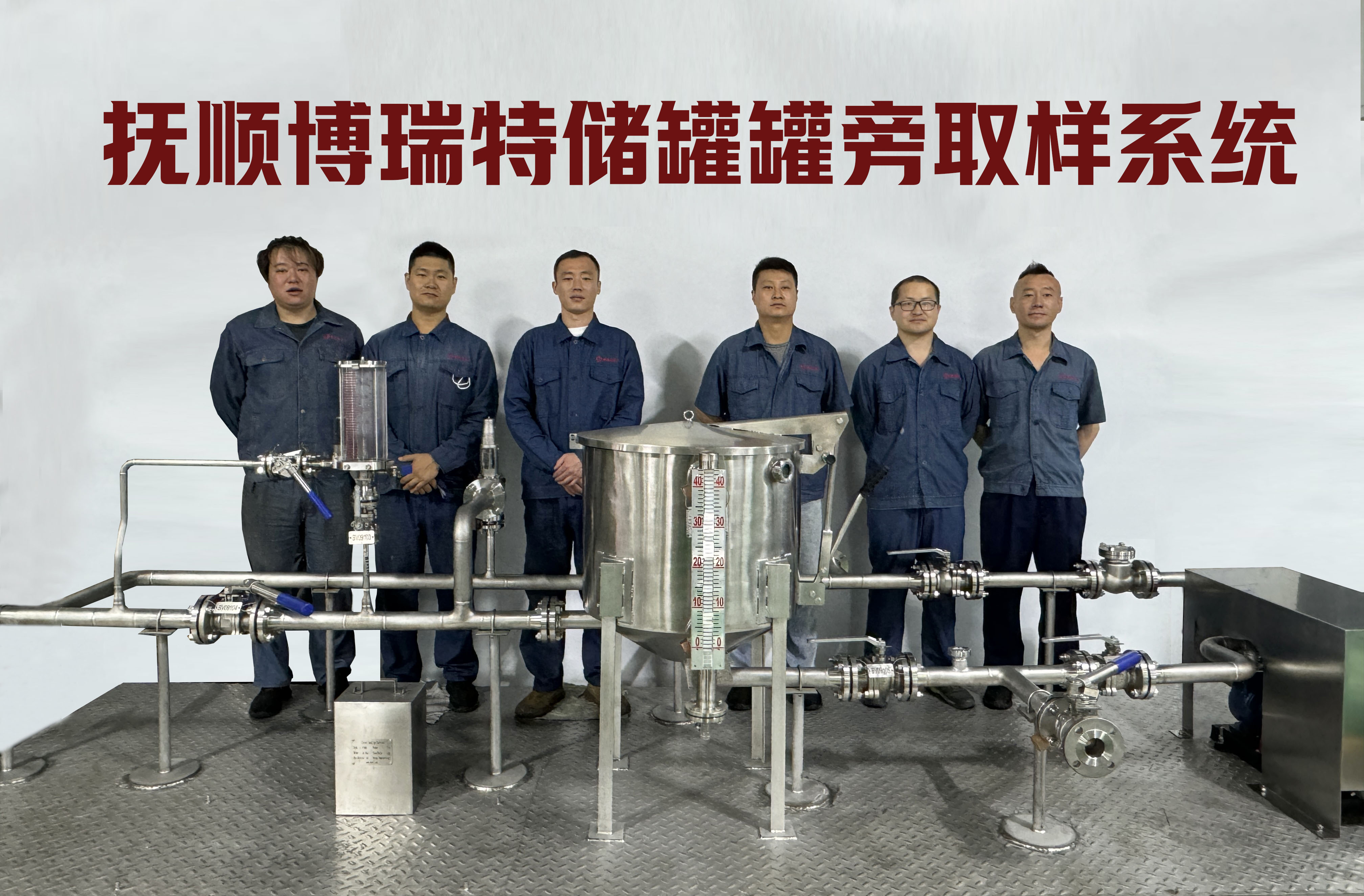

In the field of aviation fuel, the purity of every drop of oil carries the responsibility of flight safety. Faced with the industry pain points of traditional sampling methods being prone to pollution, cumbersome operation, and high oil loss, Borui Te, with its profound technical accumulation and innovative spirit, has devoted itself to creating a new generation of intelligent tank side sampling pry system. With a full process closed-loop design, intelligent control, and multiple safety guarantees, it has set a new benchmark for aviation fuel quality management.

Precise core, eliminating pollution risks

The core component of the system, the closed-circuit sampler, is tailored specifically for the harsh characteristics of aviation fuel. Its revolutionary fully enclosed design forms a tight barrier throughout the entire sampling process, completely isolating the intrusion of air, moisture, particulate matter, and microorganisms. This not only fundamentally guarantees the absolute purity of the sample, but also ensures the authenticity and reliability of key quality testing results such as flash point, water separation index, and cleanliness. The transparent and visible design allows operators to visually observe the real-time status of the collected oil products, truly achieving the quality control of "seeing is believing".

Smart sedimentation achieves zero loss of oil products

The specially designed aviation kerosene quality inspection tank is the intelligent center for the system to achieve efficient utilization of resources. It accurately receives and processes the oil products discharged by the closed-loop sampler before and after sampling (pipeline flushing and emptying stage). These oil products may contain residual dead oil or settled impurities in the pipelines, which are separated by efficient settling in the tank - heavier free water and solid particles settle to the bottom of the tank. Intelligent system diversion: safely discharge oil containing impurities at the bottom into the sewage pipeline; The clarified and qualified oil products in the upper part are automatically returned to the storage tank through the built-in oil discharge pump after observation and confirmation. This design significantly reduces oil waste and effectively lowers operating costs, especially suitable for key nodes such as airport oil depots, port oil depots, and large storage tank areas.

Seven innovative advantages empower excellent operations

The Boret tank side sampling pry system integrates cutting-edge technology and comprehensively improves the safety, convenience, and economy of operation through multiple innovative designs

Valve precise positioning (valve tag number): Each process valve is assigned a unique identifier (Tag Number), like the "precise coordinates" of the operation. This not only eliminates communication ambiguity, but also enables quick positioning of target valves for maintenance, calibration, or replacement, providing solid support for standardized operations and safety management systems.

Intelligent leak prevention guard (valve self rebound technology): The inlet valve of the closed-circuit sampler, the inlet valve of the quality inspection tank, and the drain valve all apply innovative self rebound technology. The built-in intelligent mechanical structure ensures that the valve automatically and reliably resets and closes when the external force is released. This technology eliminates the risks of medium leakage and volatile organic compound (VOC) emissions from the source, effectively ensuring the occupational health and environmental safety of personnel.

Process Transparent Window (Mirror): Integrated mirror device provides real-time monitoring window for operators. Without frequent opening of the lid, the liquid level changes of the quality inspection tank and the flow state of the medium in the pipeline can be clearly observed, greatly reducing the risk of contamination caused by opening the lid and reducing the frequency of manual inspections.

Pressure safety barrier (safety valve): When the system pressure rises abnormally and exceeds the preset safety value, the safety valve will automatically and quickly open to release pressure, providing crucial overpressure protection for the entire sampling pry and ensuring equipment and personnel safety.

Steady Flow Guard (Unidirectional Valve): Strictly ensure that the fluid flows only in one direction along the set direction, effectively preventing any possible backflow and ensuring the stability and reliability of the process flow.

Pump body protection expert (anti vortex device): The anti vortex device cleverly installed in the quality inspection tank effectively optimizes the fluid flow state and eliminates harmful vortices. Prevent air from being sucked into the pipeline and causing pump cavitation, significantly extending the service life of the pump and ensuring its long-term stable and efficient operation.

Clear liquid level navigation (flip plate level gauge): The flip plate level gauge adopts the magnetic coupling principle, which drives the prominent red and white dual color flip plate outside the tank to accurately and synchronously flip with the liquid level. No external power supply is required, the display is intuitive and clear, the maintenance is simple and convenient, and the liquid level height is clear at a glance, which is an important guarantee for safe operation and efficient management of the tank area.

Choose Borui Te, choose the future of value

The Boret tank side sampling pry system is not only a set of equipment, but also a strategic partner for you to improve the quality management level of aviation fuel, achieve cost reduction and efficiency improvement, and practice green environmental protection. It represents:

Ultimate purity: closed-loop sampling, isolation of pollution, ensuring absolute accuracy of detection data, laying a solid foundation for flight safety.

Worry free safety: intelligent leak prevention, multiple pressure relief, flow control, building a comprehensive safety guarantee system.

Efficient and intelligent: clear identification, visual monitoring, automatic reset, simplified operation process, and improved work efficiency.

Economic and Environmental Protection: Intelligent recycling of oil products reduces losses, intelligent leak prevention reduces VOC emissions, significantly reduces operating costs, and fulfills environmental responsibilities.

Borui Te - Driven by innovative technology, redefining new standards for tank side sampling!